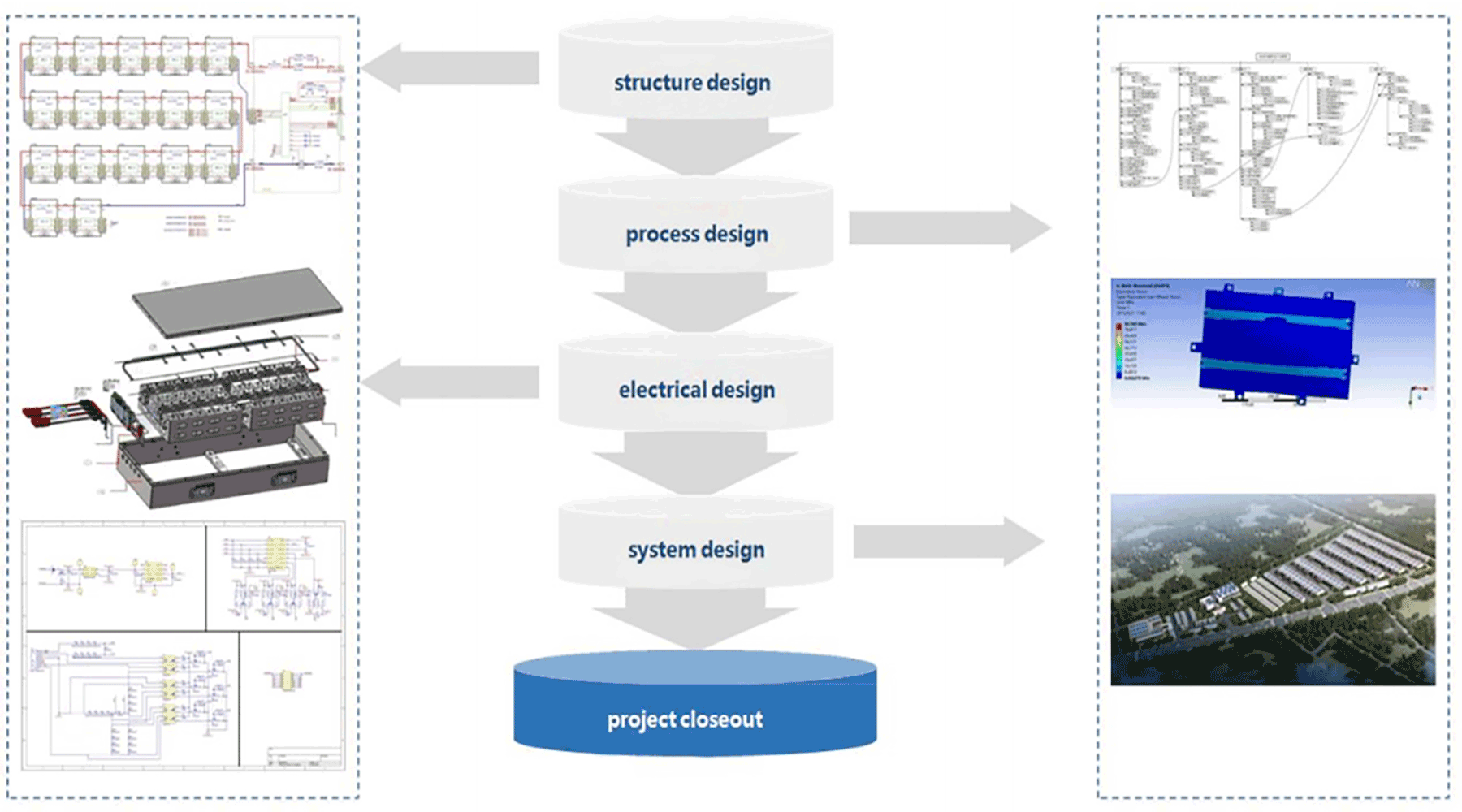

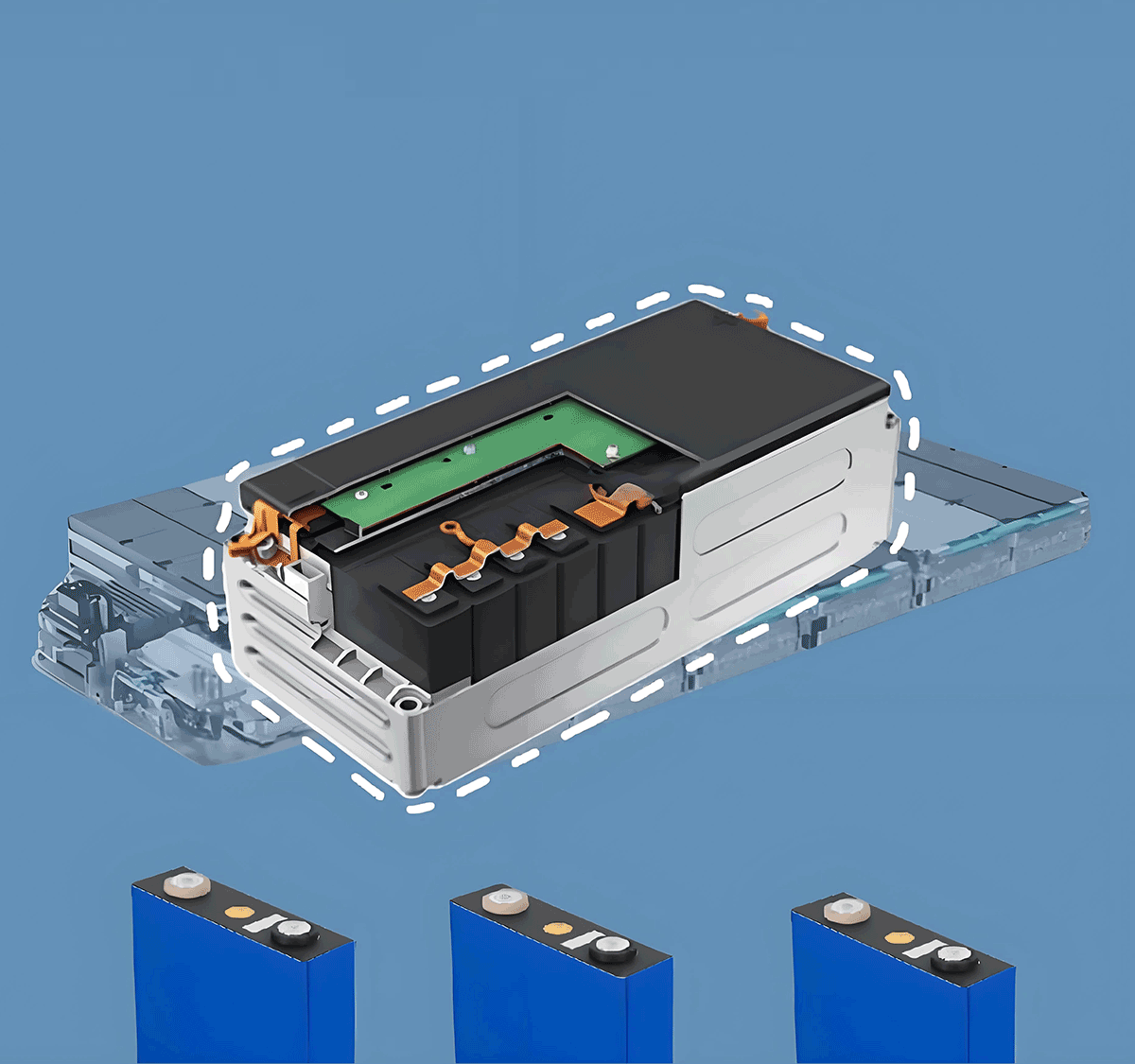

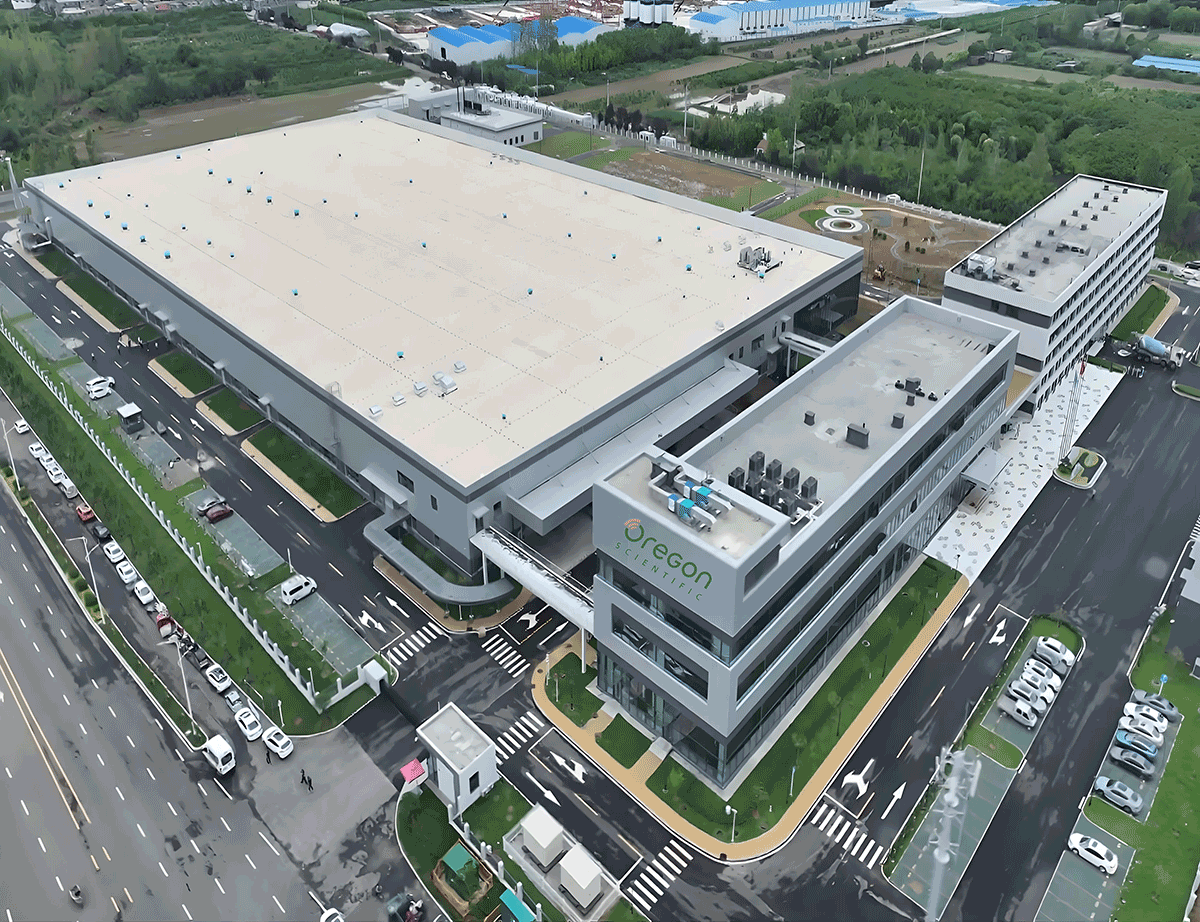

Oregon(SY)Amperex Technology specializes in customizable new energy battery solutions tailored to diverse applications, from EVs to industrial systems. We engineer bespoke configurations in cell chemistry, form factors (cylindrical, prismatic, pouch), and energy density (50-500Wh/kg) while meeting strict voltage/capacity specifications. Leveraging agile R&D and modular production lines, we deliver prototypes within 30 days and full-scale solutions compliant with ISO/UL/IEC standards. Our cross-functional team collaborates closely with clients throughout the lifecycle—optimizing thermal management, BMS integration, and scalability for evolving needs. This turnkey approach ensures performance-driven power solutions that outpace industry benchmarks.

ROHS Test

ROHS Test

Li-Ion content test

Li-Ion content test

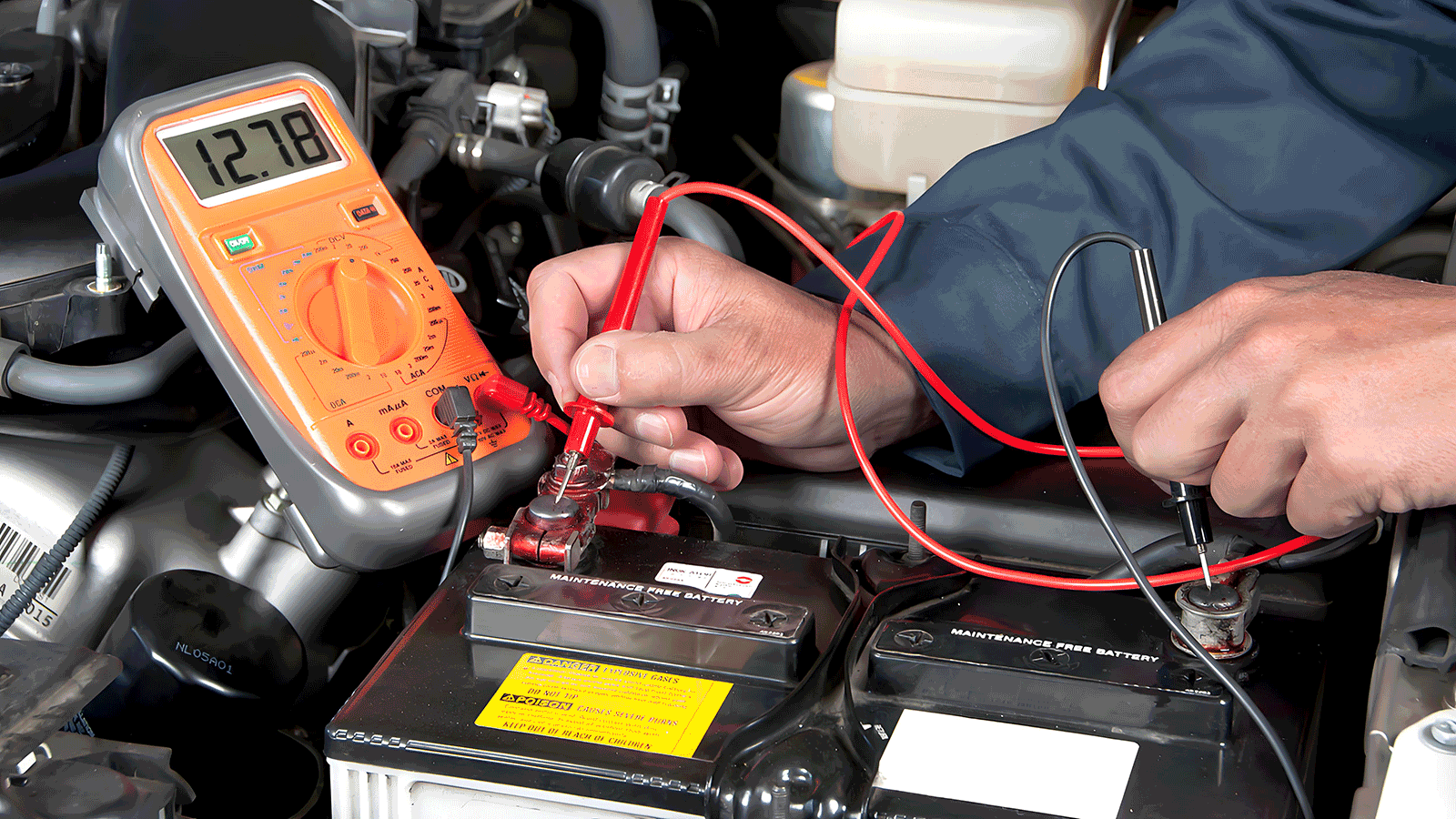

Cycle life and power test

Cycle life and power test

Temperature and short-circuit test

Temperature and short-circuit test

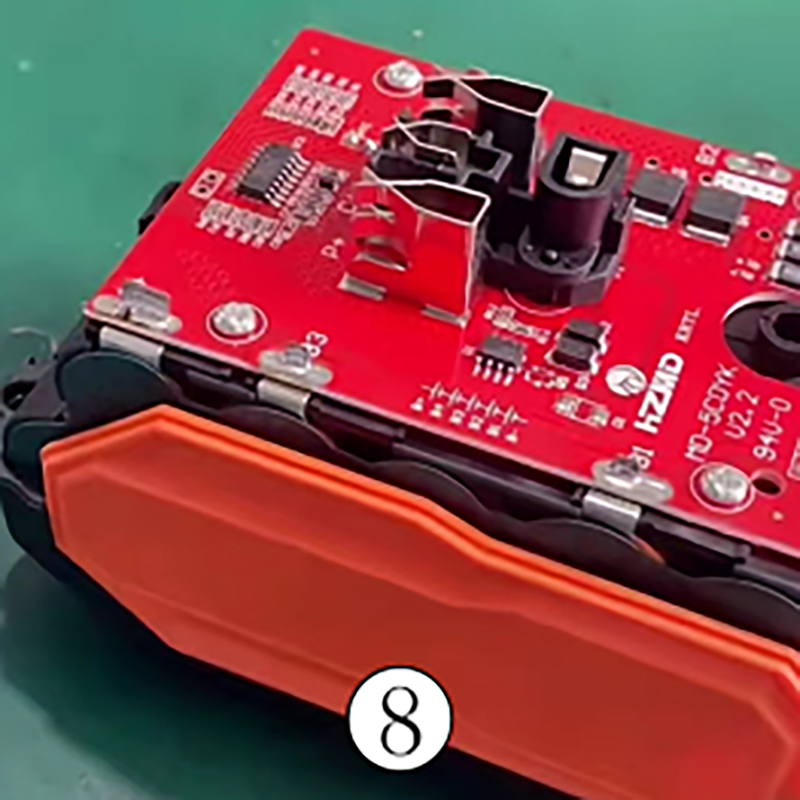

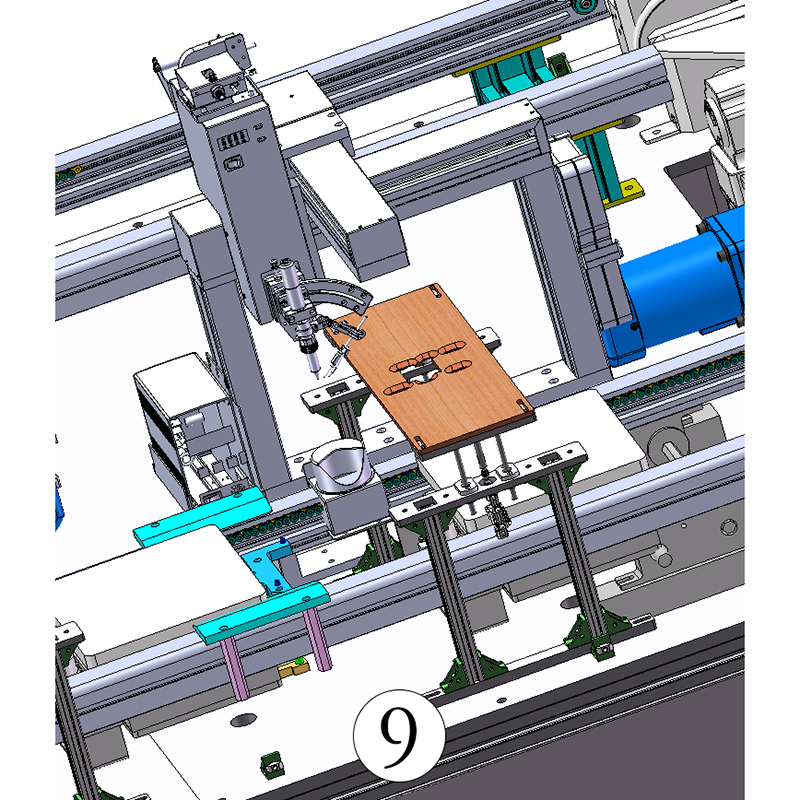

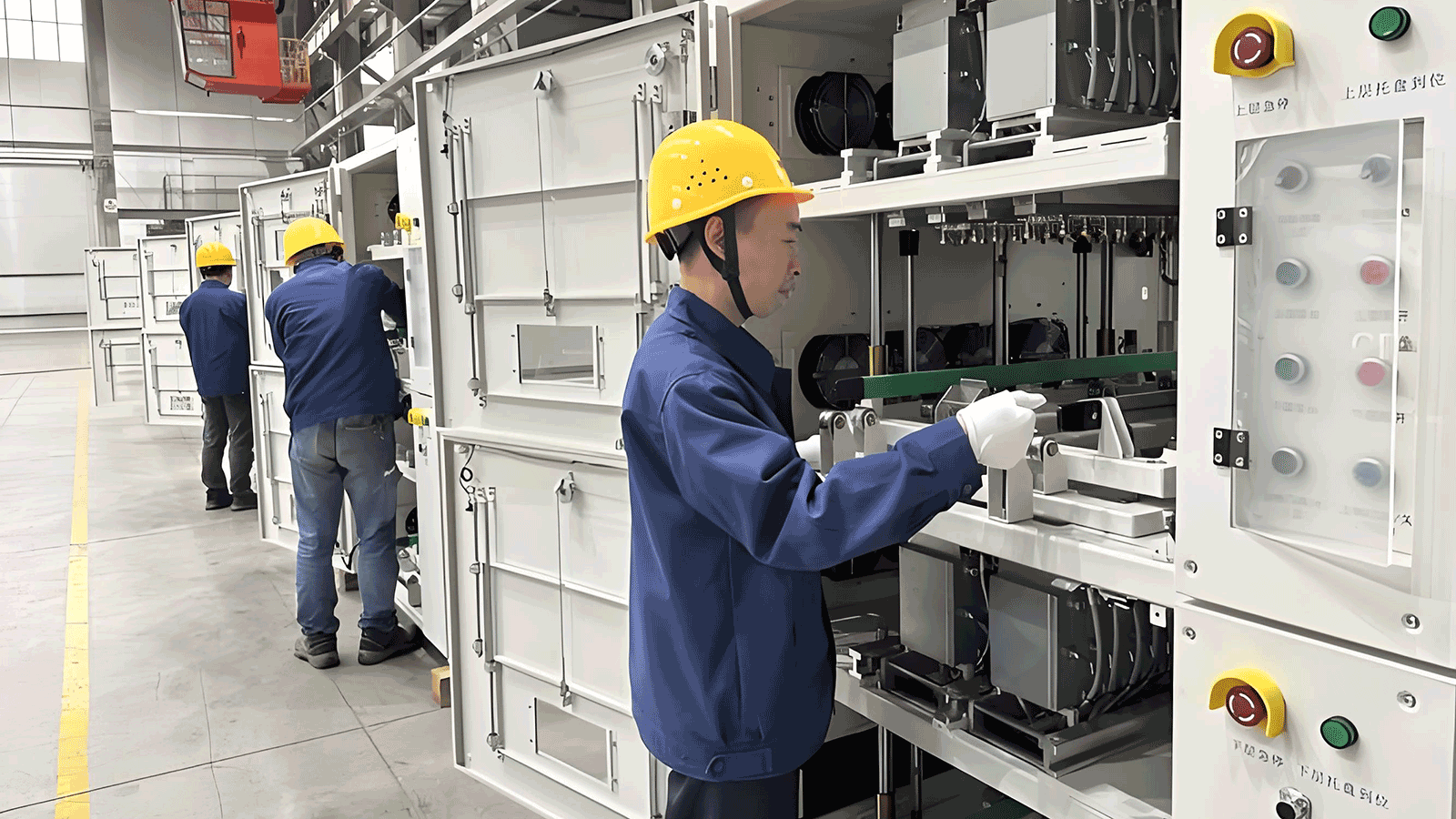

Module testing

Module testing

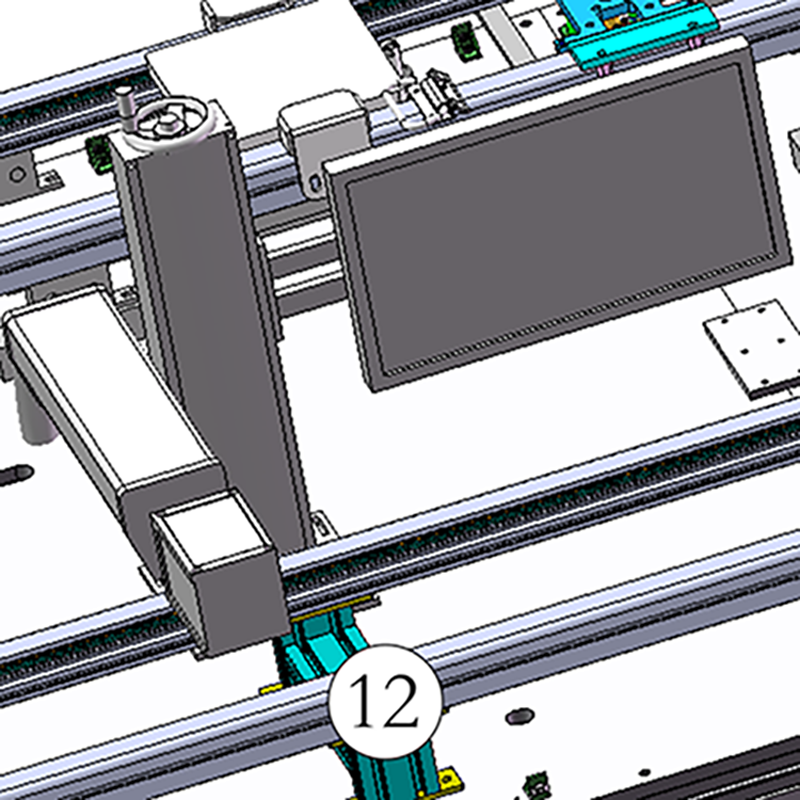

System testing

System testing